| Sign In | Join Free | My ecer.com.ru |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ecer.com.ru |

|

Brand Name : Ellison

Model Number : CGF24-24-8

Certification : CE/ BV / ISO

Place of Origin : Jiangsu, China

MOQ : 1 set

Price : Negotiation

Payment Terms : T/T, L/C, Western Union, MoneyGram

Supply Ability : 10 sets per month

Delivery Time : 30 working days

Packaging Details : Wooden case or pallet package

Machine type : New washing filling capping machine

Machine structure : 3 in 1 filling machine

Capacity : 8000-10000BPH

Control manner : PLC and touch screen

Suitable bottle : PET bottle

Filling range : 330ml-1500ml

Driven type : Electric

Power supply : 380V 3phase 50/60HZ

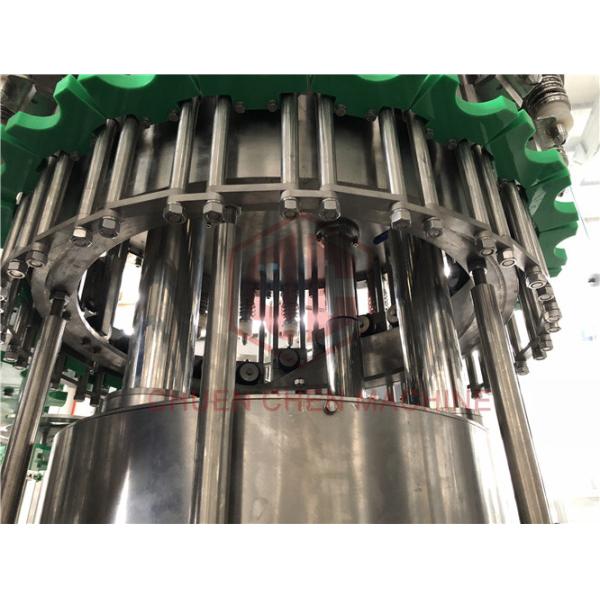

Air Conveyor Feeding Drinking Water Bottle Filling Machine 3 In 1 PET Line

General information

| Machine type | Monoblock 3 in 1 Washing filling capping unit |

| Filling material | Mineral water |

| Production capacity | 8000-10000BPH / Basing on the requirement |

| Filling range | 330ml-2000ml |

| Bottle type | Plastic bottles |

| Cap type | Plastic screw caps |

Description

Water bottle filling machine is used to fill mineral water into plastic bottles. The filling range can be from 150ml-2000ml with the same bottle necks. All the changeovers are updated into one piece which is convenient for client operation.

This filling machine is the new / updated design for filling water.

Features

| Machine structure | New type: round corner, Arm control |

| Material | Water touch parts are stainless steel 304 or 316L All the parts are manufactured in more precise |

| Each unit features | Washing Part: 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing |

| Additional function | Install central lubrication system |

Technical specification

| Complete solution of water production line 2000BPH – 20000BPH | PH≥4.6 Drinking water | |||

| Mineral | Shape | Filling volume | Filling level (mm) | Neck type |

| PET bottle | Round or square bottle | 100-2000ml | Distance from bottle neck | Basing on the real sample |

| Bottle type | Diameter ≤ 105mm; height ≤ 335mm | |||

| Changeovers will be needed if having different bottle; Regarding the bottle in square shape, the bottle separating system will be needed; | ||||

| Labeling manner | Packing system | Palletizing system | ||

| Package | Format | |||

| Hot glue OPP PVC shrink label Full label / Half label Manual type / Auto type | Manual Film shrinker Wrap around Packer Robert packing Machine | 1*2 2*3 3*4 4*6 3*5 | Manual Low position gantry Palletizer Robert Palletizer High position gantry Palletizer Single arm palletizer Manual palletizer | |

| Working environment | Temperature: 10-40 degrees Celsius; Humidity: No dew | |||

| Power supply | 380V 3phase 50HZ / Customize | |||

| Model | CGF24-24-8 |

| Capacity | 8000-12000 BPH for 500ml bottle |

| Suitable bottle | PET round or square |

| Bottle diameter | 50-115mm |

| Bottle height | 160-320mm |

| Air consumption | 0.5CBM / min |

| Air pressure | 6-8bar |

| Total power | 5.2kw |

Electric configuration

| 1 | Motor | ABB / Swizerland |

| 2 | Electric protection switch | Schneider / Germany |

| 3 | Circuit breaker | Siemens / Germany |

| 4 | PLC | Mitsubishi / Japan |

| 5 | Touch screen | Siemens / Germany |

| 6 | Transducer | Turck / Germany |

| 7 | Photoelectricity switch | Banner / USA |

| 8 | Pneumatic element | Festo / Germany |

| 9 | Contactor | Siemens / Germany |

| 10 | Converter | Mitsubishi / Japan |

Option machines

| Online cap washing system | Including: cap tunnel, stainless steel frame, washing head, two sets of washing pump and two sets of recycling tanks in stainless steel 304. |

| Cap elevator | Air consumption:0.3kg Air blower: 0.25kw Rotary: 2800rpm Power:0.18kw Rotary:1360rpm Machine size: 600*600*1800mm Weight:150kg |

FAQ

Q: How to get an appropriate offer?

A: Please inform us:

1, production capacity per hour/per day/per month ... ...

2, filling liquid: water, juice, carbonated drink, beer or ... ...

3, bottle type: plastic bottle, glass bottle, can or ... ...

4, cap type: screw cap, crown cap, can lid or ... ...

5, for water treatment, it's better offer us the raw water quality report ... ...

Q: What can I do if I haven't gotten any clue of the production line? I just wanna open a factory and to do the business.

A: Don't worry about this; You can inform us:

1, the exact production you wanna deal with;

2, the budget of the production line; If no budget of the business, I will send you the popular machine in our factory for your ref;

3, we will help tp design everything including the machine layout and factory layout;

Q: This is the first time I cooperate with your factory. How can I trust you about the machine quality?

A: Before ordering the machine, we will make the offer very clear. For example, the material thickness, the brand etc. We can have the video call and I will show what we have in the factory;

Also you can visit us to see the machine;

Detailed photo for ref

|

|

3 In 1 Water Bottle Filling Machine Images |